Automotive and Transportation Industries

Belleville washers also find extensive use in the automotive sector, where reliability is paramount. By securing crucial components in suspension systems, clutch assemblies, and engine mounts, they contribute to smooth and stable vehicle performance.

Energy and Distribution Sectors

In the energy industry, Belleville washers are vital components in pumps, valves, and pressure vessels, as well. They help ensure proper bolt tension, resisting vibrations and pressure changes that could compromise the integrity of these critical systems.

High-Temperature Applications and Corrosive Environments

American Belleville washers can also stand out in high-temperature and corrosive environments where quality is essential. They are engineered to endure extreme conditions, such as those encountered in chemical processing plants and utility transmission systems.

Precision in Industrial Automation

In industrial automation, Belleville washers are widely used to ensure reliable and precise performance in robotics, CNC machinery, and other automated systems. They aid in maintaining the necessary preload on bolts, which not only prevents undesirable movements, but also guarantees consistent operation.

Resolving Thermal Expansion and Bolt Yield

Finally, versatile washers excel in applications where thermal expansion and bolt yield need to be under careful maintenance. They provide essential flexibility, accommodating thermal fluctuations and minimizing the effects of relaxation.

Browse Our Catalog or Contact Us Today

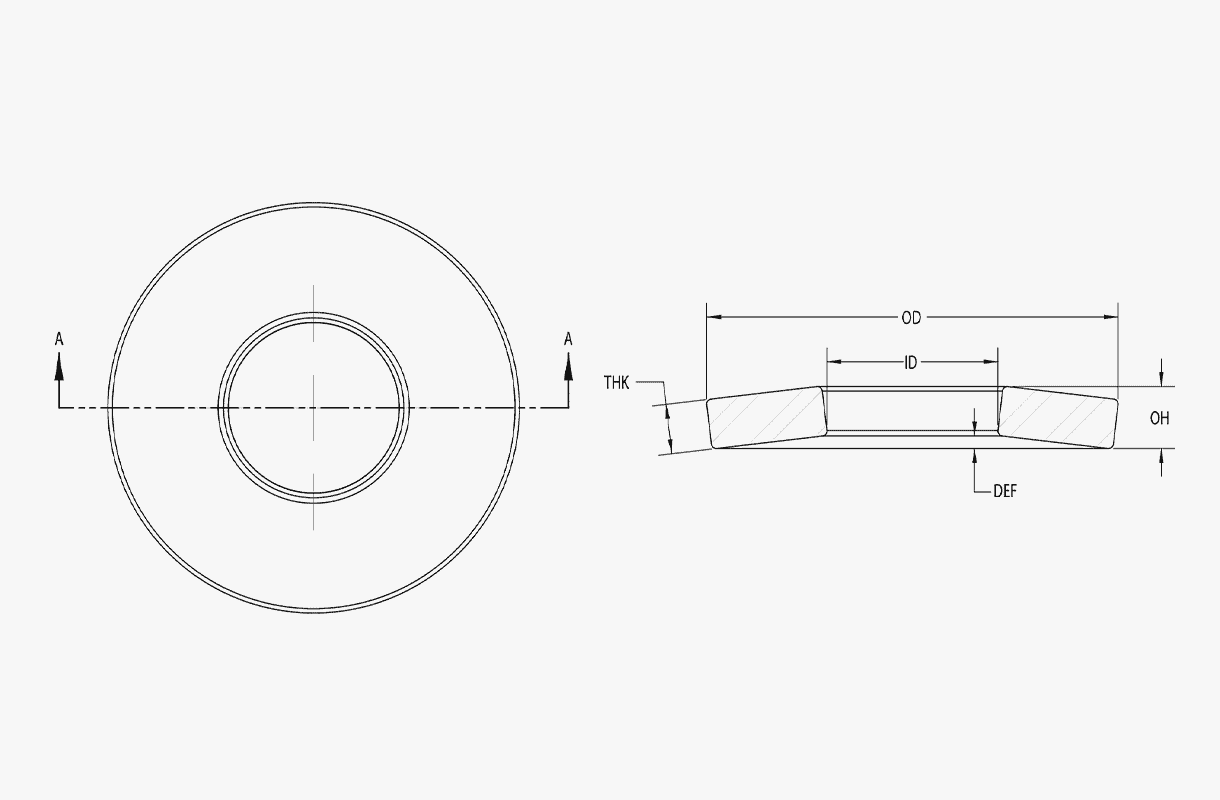

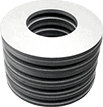

Belleville washers, or conical washers, are unassuming yet indispensable components found in numerous industries. Their ability to prevent fastener loosening, absorb shocks, and maintain bolt tension makes them invaluable across automotive, energy, industrial automation, and various other sectors. American Belleville washers, specifically engineered for high-temperature and corrosive environments, also stand as a testament to the unwavering commitment to quality and reliability. From automotive to industrial automation, our Belleville washer catalog demonstrates the power of precision engineering in safeguarding the integrity and efficiency of critical systems. Furthermore, as industries continue to evolve, the versatile applications and uses of Belleville washers will undoubtedly remain at the forefront of innovation and progress. So, contact us today to learn more about our washers.