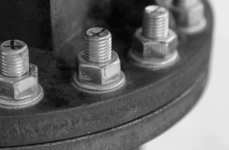

Why Is Bolt Torque Important?

You must ensure that your application has the appropriate amount of torque and tension to avoid bolt shearing (sliding apart) and tensile (pulling apart) forces. After the nut has been turned onto the bolt, additional torque causes the nut to turn and stretch the bolt. When the bolt stretches, it becomes a solid spring that clamps the components together. The components won’t be pulled apart if the clamp load is not exceeded by the tensile load. Under shear loads, the increased friction prevents relative motion of the components, preventing material failure.

Determining the appropriate amount of torque depends on the metal properties of the bolt and the purpose of the bolt. Essentially, you need to make sure that you have the right materials for your application. Having the wrong materials, or an incorrect torque calculation can be potentially hazardous. An under-torqued bolt will deform and won’t be able to provide as much clamping force as needed, while an over-torqued bolt will break.

How to Calculate Torque

To determine an estimated torque value, use the standard torque formula:

T = DFK

This formula expresses the relationship between the load in a bolt and applied torque. The “D” represents the bolt’s diameter, the “F” is the axial bolt force, and the “K” represents “k-factor” or “nut factor” which is a variable based on the use or absence of lubrication. The k-factor for a non-lubricated joint is 0.2. Non-lubricated joints are typically referred to as being “dry”, and the process of torquing down the joint being known as “dry-torquing”. The k-factor of a lubricated joint is typically between 0.15 and 0.18.

A non-lubricated or dry joint has more friction between components which requires more torque to be applied in order to achieve the same deflection/travel as a lubricated joint. These factors are best determined after a great deal of experimentation through extensive testing.

An Example of Calculating Bolt Torque

For this example, our K will be 0.2 for a non-lubricated joint. Our bolt’s diameter will be 0.5 inches, and the axial bolt force will be 11,175 lbs:

T = 0.2 x 0.5 x 11,175

T = 1,117.5 inch lbs.

Then, convert to foot pounds by dividing by 12:

T = 1,117.5 / 12

T = 93.125 ft lbs

Our T in this equation is approximately 93 ft. lbs.

Use a Torque Wrench to Calculate Torque

Torque wrenches are precision instruments that will allow you to measure and apply the proper torque for the results you need. Torque wrenches will calculate the amount of torque in either analog or digital formats. When calculating torque, always remember that torque wrenches are not perfectly accurate. If you’d prefer, please contact us regarding the optimal torque for various combinations of bolt diameter, thread type, and grade or class.

How to Verify Your Torque Calculation

Once you have calculated your torque, be sure to double-check to confirm that the calculation is correct to ensure the safety and proper functioning of your equipment. A small error could result in a large discrepancy in your final figure. To verify your torque calculation, use these three proven methods:

The First Movement Test

After you’ve tightened your fastener, use a torque audit wrench to slowly apply force in the tightening direction until you notice the first movement in the fastener. The reading is a reliable indication of the originally-applied torque. This is the most trusted measure of torque after tightening.

The Loosening Test

This is the same as the first method, except in the opposite direction. The moment in which you feel the first loosening movement will create a good reading on your audit wrench.

The Marking Test

Mark the surface of the fastener after tightening the bolt or nut, and continue that mark to the surface that it’s being fastened to. Now loosen the fastener, wait a moment, and re-tighten until the marks you just made align. The torque required to get to that point is a good reference to the original torque used.

Questions?

If you have questions about how to calculate the tightening torque of bolts for your application, please fill out the contact form at the bottom of this page, or give us a call at 440.721.8350.