What Are Belleville Washers?

Shaped like a conical disk with a hole in the center, these handy little parts have robust nonlinear force-deflection characteristics that can limit the effects of bolt relaxation, resolve thermal expansion, and deter bolt yield. Belleville washers are most commonly used to support fasteners in two ways:

- Prevent the fastener from vibrating loose

- Dampen and absorb shock that might damage the joint’s integrity

Their cup-like shape makes them superior to flat washers in terms of pressure response. When pressure is applied, they flatten to absorb the vibrations and shocks. And because the relationship between load and deflection is non-linear—especially with an increasing load—washers are ideal for applications associated with constant thrust and heavy wear.

Their design enables them to easily dissipate strong compressive forces of various applications like machine tools, pipe flanges, or gun recoil mechanisms.

Purpose of Stacking Belleville Washers

A single Belleville washer is capable of handling a variety of high-pressure loads. But, there are some limitations since its mechanical design has a specific load for a given deflection. As a result, certain applications will have load or deflection requirements that far exceed a sole washer’s tolerance.

This is where a bVelleville disc spring stack design calculator can make a difference.

The number of washers stacked and the configuration of the stack can greatly increase the load bearing or the deflection capacity.

There is a lot of high-level mathematics and advanced mechanical engineering that goes into these stacking equations. We’ll save you from the nitty-gritty. Just know that each configuration has a calculated load/deflection ratio to address specific applications.

How To Stack Belleville Washers

While there may be dozens of different stacking configurations, they all boil down to one of the following stack combinations.

#1 Parallel Stacking

A parallel stack configuration occurs when you place all the washers facing the same direction. This won’t increase deflection. But it will increase load capacity with each washer added to the stack.

In theory, two washers stacked in parallel would yield double the load; three washers would triple the load; four stacks would quadruple the load, and so on. However, in reality, parallel stacks suffer load loss due to friction between springs. As a result, experts recommend that you never stack more than four springs in parallel.

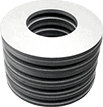

#2 Series Stacking

With a series stack, the washers are stacked in opposite directions to create a gap in the middle and a spring-like shape. This doesn’t increase load capacity, but it can significantly impact the deflection of the stack.

When stacked in this manner, the deflection is multiplied by the number of springs in a series.

For instance, if the deflection of a single spring series was .025 inches, the deflection of a triple spring series would be .075 inches.

#3 Parallel/Series Stack

If a parallel stack increases load and a series stack increases deflection, a configuration that utilizes both stacks will simultaneously increase load and deflection.

With this type of stack, you could arrange the parallel and series stacks in countless different ways to suit practically any application.

American Belleville: Premium Quality Belleville Washers

Belleville washers are designed for a high load capacity in small spaces. And by stacking them in a specific configuration, you can greatly increase the load/deflection rating to match the job requirement.

But, to get the most out of your Belleville stacks, the materials matter.

At American Belleville, our washers are made with the highest-quality materials available in order to achieve added load or greater deflection. They’re designed to accommodate working temperatures ranging from -400 degrees to 1,100 degrees, as well as highly corrosive environments.

When it comes to conical washers, flange washers, and disc springs, American Belleville has the solution. No matter the use or stack configuration, our products are precisely manufactured to not just meet but exceed your expectations.

Contact Us