Corrosion Resistance

Stainless steel is known for its exceptional resistance to corrosion, making it ideal for use in environments where exposure to harsh chemicals, saltwater, and other corrosive elements is common.

High Strength

Belleville Washers are renowned for their strength, ensuring they can withstand extreme pressures and loads. This is essential in oil and gas applications where equipment must endure significant stress.

Temperature Resistance

Stainless steel maintains its mechanical properties over a wide range of temperatures. This is crucial for equipment used in the oil and gas industry, where temperature variations can be extreme.

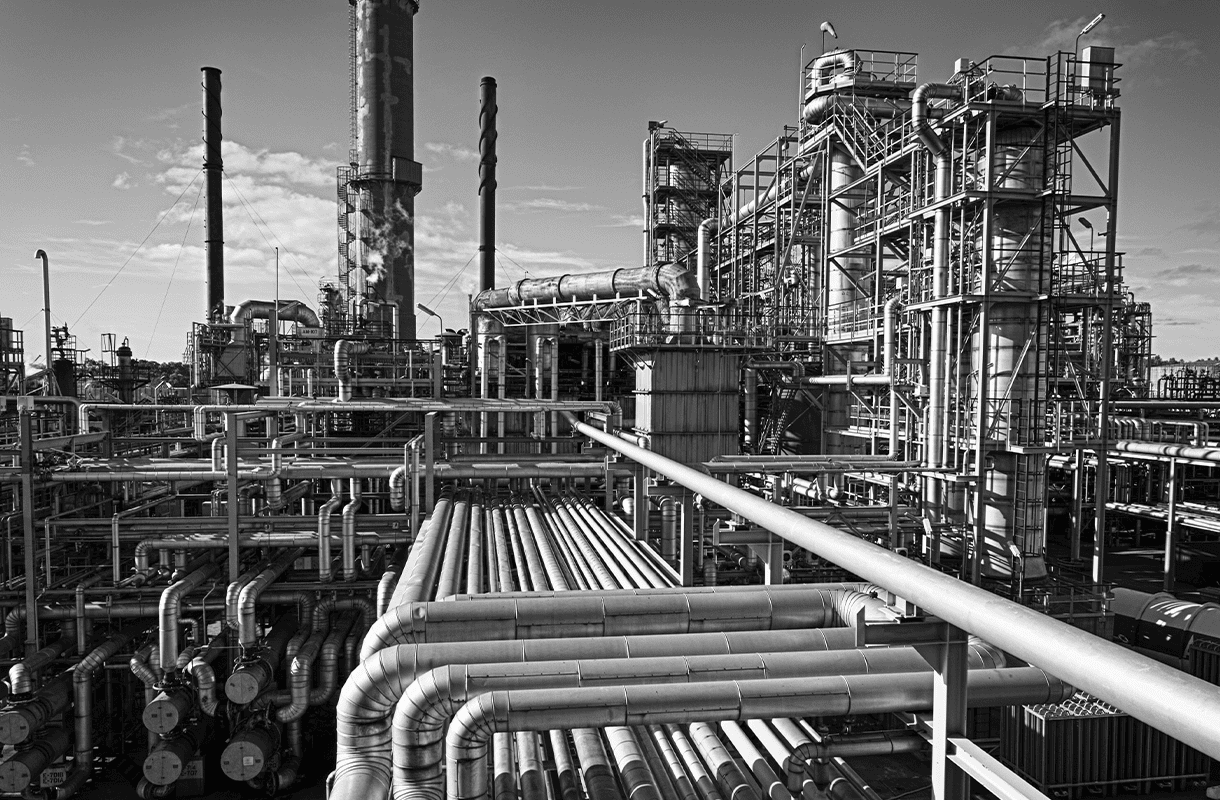

Applications of Stainless Steel Belleville Washers in the Oil & Gas Industry

Valve Assemblies

Belleville Washers are commonly used in valve assemblies to maintain the necessary preload on the packing and stem seals. This ensures the valves remain leak-tight under high-pressure conditions.

Flange Connections

Flange connections in pipelines require consistent sealing to prevent leaks. Belleville Washers are used to maintain the necessary gasket load over time, guaranteeing a reliable seal.

Pressure Relief Systems

In pressure relief systems, Belleville Washers are used to control and release excess pressure safely. These washers provide a reliable way to maintain the set pressure, ensuring that equipment remains within safe operating limits.

Subsea Equipment

The oil and gas industry often involves underwater operations. Belleville Washers are employed in subsea equipment to maintain the required preloads and compensate for thermal expansion and contraction in the harsh subsea environment.

High-Pressure Equipment

In high-pressure applications such as hydraulic systems and downhole tools, Belleville Washers provide the required spring force to maintain seal integrity and ensure proper functionality.

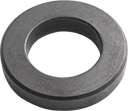

Trust American Belleville for Your Stainless Steel Belleville Washers

Belleville Washers are indispensable components in the oil and gas industry, where equipment reliability, safety, and performance are paramount. Their ability to resist corrosion, withstand extreme pressures and temperatures, and maintain preload over time make them a preferred choice in critical applications.

American Belleville, as a leading belleville washer manufacturer, plays a vital role in ensuring the availability of high-quality Belleville Washers to meet the demands of the oil and gas industry. With their resilience and durability, stainless steel Belleville Washers contribute to the success and safety of oil and gas operations, making them an essential component in this dynamic and challenging sector.