What Are Some Belleville Washer Applications?

Belleville washers are often used for the following applications:

- Securing heavy loads – The axial force applied by a Belleville washer helps fasten heavier loads to structures with less risk of movement around the hardware (e.g., “sagging” due to gravity).

- Spring applications in tight spaces – Coil springs generally result in a significant amount of compression “travel,” which increases their overall length. This limits their usage in tight spaces, whereas a Belleville washer’s limited movement and greater load capacity make them the perfect hardware for these locations.

- Applications subject to vibration – The inherent deflection provided by a Belleville washer will absorb vibrations, shock, and other forces that can loosen fasteners, making them an essential piece of hardware for some machinery and equipment.

- Applications subject to thermal changes – Metals expand with temperature increases and contract with decreases, which changes the stress placed on the hardware. A Belleville washer’s ability to maintain preload via deflection will minimize these effects on fasteners.

- Minimizing bolt creep or relaxation – Belleville washers minimize the occurrence of “creep” (i.e., the loss of tension from high-stress applications that permanently deform hardware) over time.

Are Belleville Washers Reusable?

Unlike some hardware, like crush washers, disc springs are reusable. However, you’ll want to inspect the hardware between uses to ensure that permanent deflection or deformation hasn’t occurred.

If it has, the washers must be replaced.

Are Belleville Washers Paired with Flat Washers?

Depending on your application, you may need to use a flat washer in addition to a Belleville washer.

Combining them ensures an even distribution of spring force. It also protects against the disc spring “biting into” or damaging either the load you’re securing or the structure it’s secured to.

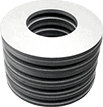

Can You Stack Belleville Washers?

Belleville washers can be stacked to achieve optimal loads and deflections. The three ways they can be stacked are:

- In parallel – You can increase the load capacity of Belleville washers by stacking them so they face the same direction. The total load capacity achieved equals the number of washers times the load one supports (e.g., two washers double the load, three washers triple it).

- In series – You can increase the deflection Belleville washers provide by alternating them when stacking so they face opposite directions. The total deflection allowed equals the number of washers times the deflection one provides (e.g., two washers double deflection, three washers triple it).

- Series parallel – You can increase both load capacity and deflection by combining the other two stacking methods. For example, you may stack two sets of parallel washers facing opposite directions.

Whatever your application, the ability to stack multiple Belleville washers in different configurations allows you to achieve the perfect amount of load support and deflection.

Get The Tools You Need At American Belleville

American Belleville provides Belleville washers, flange washers, and disc springs manufactured to meet peak engineering performance and withstand the most rigorous applications—at globally competitive pricing. We also act as consultants.

That said, we started American Belleville with the mission of providing industry-best customer service. Our experts know that the same washer doesn’t suit every purpose, and we’re committed to always finding the perfect solution for your needs and delivering it quickly.

If you have questions about which Belleville washer best fits your application, please fill out the contact form at the bottom of this page, or give us a call at 440.721.8350.