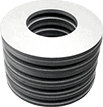

Disc Spring Design

The design can impact their load-bearing capacity, deflection properties, and stress distribution. High-quality disc springs are designed with accurate specifications and tolerances that meet or exceed industry standards.

The design should also take into account the specific application requirements, such as temperature, pressure, and cycle life, to ensure optimal performance and safety. American Belleville’s state-of-the-art designs ensure maximum load bearing.

Testing and Certification

The final step in identifying high-quality disc springs is to verify their performance through testing and certification. Reputable manufacturers, such as American Belleville, perform rigorous testing on their disc springs to ensure they meet the specified requirements for load-bearing capacity, deflection, and fatigue resistance.

Trust American Belleville With Your Disc Spring Needs

Identifying high-quality disc springs requires careful consideration of several factors, including material composition, manufacturing process, design, and testing. By selecting high-quality disc springs from American Belleville, you can ensure the safety, reliability, and longevity of your mechanical applications. Choose American Belleville, where we adhere to strict quality control standards and provide excellent customer service and support. Ask for a disc spring quote here!