Belleville Washers

Not what you are looking for, select an option below?

![]()

American Belleville washers hold your bolted joint tight in the face of the most extreme cases of differential thermal expansion/contraction, bolt creep and vibration that threaten the integrity of the joint. We specialize in high-temperature applications and the most corrosive environments where first-rate quality is not just important, but necessary.

High-Quality Belleville Spring Washers

Offering a design that allows for very high load capacity, relative to deflection and available space within the application, American Belleville washers can be specified using limitless dimensional configurations and load/deflection ratings. Whether the Belleville washer needs to fit tightly under the head of the bolt or provide a wide bearing surface across the mating flange, our products offer long fatigue life, predictable and consistent performance, and the reliability that may be missing in your current solution.

Consider American Belleville your support system when it comes to conical washers, flange washers, and disc spring needs. Our expert staff will provide you with the best products and advice to help you in every step of your process. Click here to learn how you can best utilize Belleville washers for your project, or contact us to request a quote or to gather more information.

Best Practices for Bellevilles and Conical Disc Springs

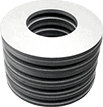

American Belleville washers may be stacked in order to achieve added load or greater deflection, as well. Available materials include:

- High-carbon Steel Alloy AISI 1074 (ASTM A684)

- AISI 6150 (50CrV4/51CrV4) Chrome Vanadium Steel (ASTM A506)

- 301 Stainless Steel (ASTM A666)

- 17/7PH Stainless Steel (ASTM A693)

- Inconel 718 (ASTM B670 / AMS 5596)

- 510 Phosphor Bronze (ASTM B103)

Our material selection will accommodate working temperatures from -400 deg. F to 1100 deg. F, various corrosive environments and magnetism requirements. Additionally, several plating/finish options for Belleville washers can achieve desired aesthetics and ensure proper resistance to environmental elements that would otherwise affect performance and longevity.

Contact us online or call 440-721-8350, we will work closely with you to specify or design and manufacture the proper part for your application.

Not finding what you’re looking for? Try:

| Item ID | Material | Bolt Dia | ID (Min) | OD (Max) | THK (Nom) | OH (Ref) | Deflection (Nom) | LBS F 100% |

|---|---|---|---|---|---|---|---|---|

| AB773-2000-154-Z | 6150 | 3/4 | 0.773 | 2.000 | 0.154 | 0.200 | 0.046 | 10800 |

| AB773-2000-155-177 | 17-7PH | 3/4 | 0.773 | 2.000 | 0.155 | 0.195 | 0.040 | 9100 |

| AB773-2250-172-Z | 6150 | 3/4 | 0.773 | 2.250 | 0.172 | 0.228 | 0.056 | 13000 |

| AB773-2250-187-177 | 17-7PH | 3/4 | 0.773 | 2.250 | 0.193 | 0.237 | 0.044 | 13800 |

| AB773-3000-135-177 | 17-7PH | 3/4 | 0.773 | 3.000 | 0.136 | 0.240 | 0.102 | 6000 |

| AB787-1850-154 | 6150 | 3/4 | 0.784 | 1.860 | 0.154 | 0.191 | 0.037 | 9400 |

| AB880-1750-85-Z | 1074 | 7/8 | 0.880 | 1.775 | 0.085 | 0.128 | 0.047 | 1760 |

| AB901-1750-125-718 | Inconel 718 | 7/8 | 0.901 | 1.750 | 0.125 | 0.155 | 0.030 | 6000 |

| AB901-1750-134-Z | 6150 | 7/8 | 0.901 | 1.750 | 0.134 | 0.167 | 0.033 | 8500 |

| AB901-1750-135-177 | 17-7PH | 7/8 | 0.901 | 1.750 | 0.136 | 0.167 | 0.031 | 7200 |

| AB901-2000-156-718 | Inconel 718 | 7/8 | 0.901 | 2.000 | 0.150 | 0.191 | 0.035 | 9500 |

| AB901-2000-154-Z | 6150 | 7/8 | 0.901 | 2.000 | 0.154 | 0.196 | 0.042 | 11000 |

| AB901-2000-155-177 | 17-7PH | 7/8 | 0.901 | 2.000 | 0.155 | 0.191 | 0.036 | 9400 |

| AB901-2250-172-Z | 6150 | 7/8 | 0.901 | 2.250 | 0.172 | 0.223 | 0.051 | 13600 |

| AB901-2250-187-718 | Inconel 718 | 7/8 | 0.901 | 2.250 | 0.187 | 0.228 | 0.041 | 13600 |

| AB901-2250-187-177 | 17-7PH | 7/8 | 0.901 | 2.250 | 0.193 | 0.233 | 0.040 | 14400 |

| AB1000-2000-65-301 | 301SS | 1 | 1.00 | 2.00 | 0.065 | 0.125 | 0.058 | 860 |

| AB1005-2000-82-Z | 6150 | 1 | 1.005 | 2.005 | 0.082 | 0.141 | 0.059 | 2600 |

| AB1005-2000-83-177 | 17-7PH | 1 | 1.005 | 2.005 | 0.083 | 0.143 | 0.060 | 2200 |

| AB1005-2000-83-718 | Inconel 718 | 1 | 1.005 | 2.005 | 0.084 | 0.136 | 0.045 | 2300 |